[ad_1]

Yesterday, I received a giant mission completed in my studio. The lengthy DIY countertop made with laminate flooring is finished! That was a frightening mission, and I’m so glad to have it checked off of my checklist.

What made it daunting was the size. That countertop is nearly 20 ft lengthy, and it took me endlessly to give you a plan to cowl that 20-foot span whereas not spending a fortune. The entire 20-foot countertop value about $300, and I’m so pleased with the way it turned out!

I can’t get the entire countertop in a single image (a minimum of not proper now with the work tables in the way in which), however right here’s a have a look at how the countertop turned out.

I’ll should take footage later within the day when gentle isn’t streaming via these entrance home windows, however that should do for now. Doesn’t that look so good?! Particularly for a $300 countertop! And the method as actually fairly easy. So let me begin firstly and present you the way I made this countertop.

I began out by slicing a single layer of three/4-inch plywood to suit on prime of the cupboards. Since I used to be utilizing MDF, I had the items lower at Dwelling Depot. MDF is actually heavy, and I don’t like having to elevate and lower these massive items myself, so I allow them to do the heavy lifting for me. 🙂 I had them lower the MDF to my completed countertop depth minus 1/2 inch, which is the thickness of the laminate flooring I might be utilizing.

I’ll have to indicate you these subsequent steps on the opposite countertop within the studio, however the course of was the identical on each.

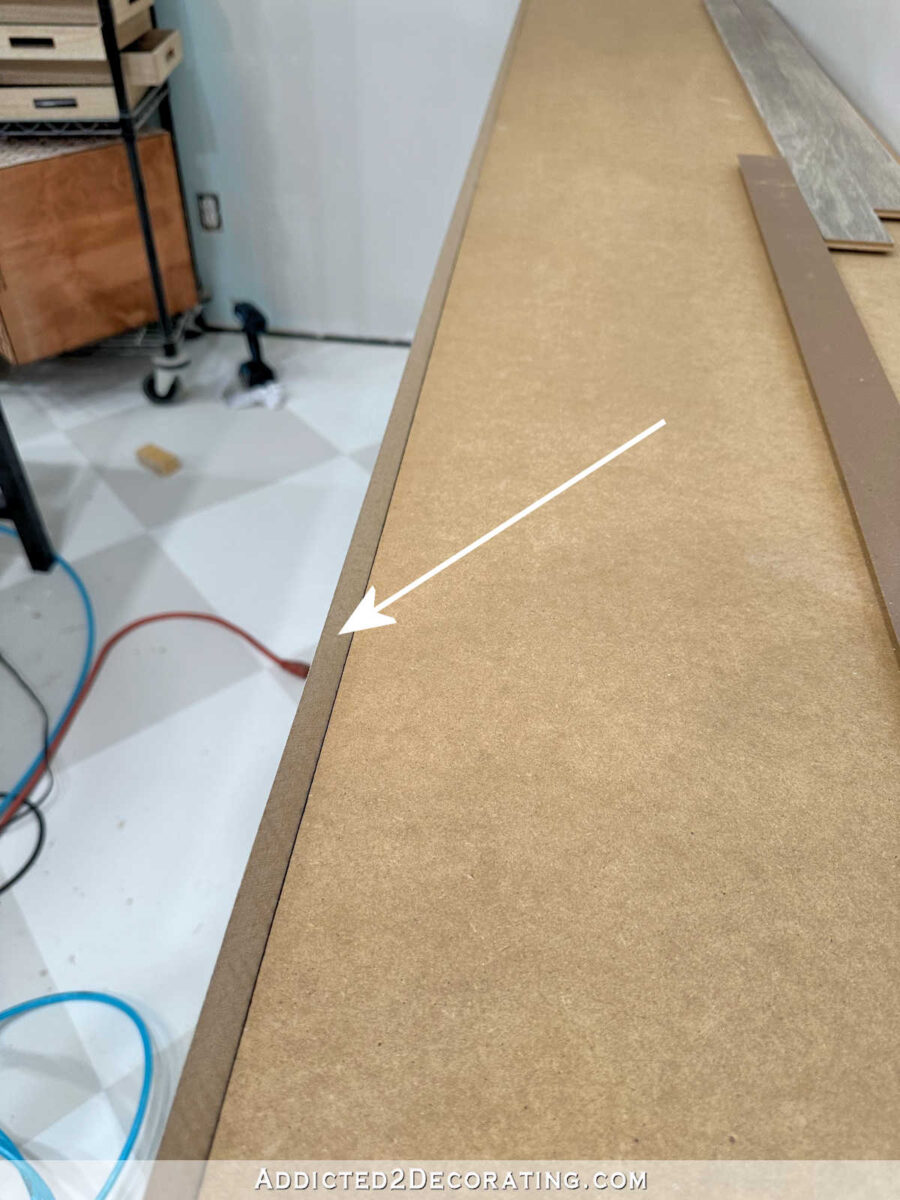

I began on the entrance and labored my technique to the again. So beginning on the entrance, I used my desk noticed to chop strips of the laminate flooring (I used this Capistrano Seashore Oak laminate flooring from LL Flooring) in order that it match the thickness of the MDF (3/4 inch on the lengthy countertop) with a 45-degree mitered edge on prime. After which I hooked up these strips utilizing wooden glue and 18-guage end nails. Right here’s a view of that piece from the entrance…

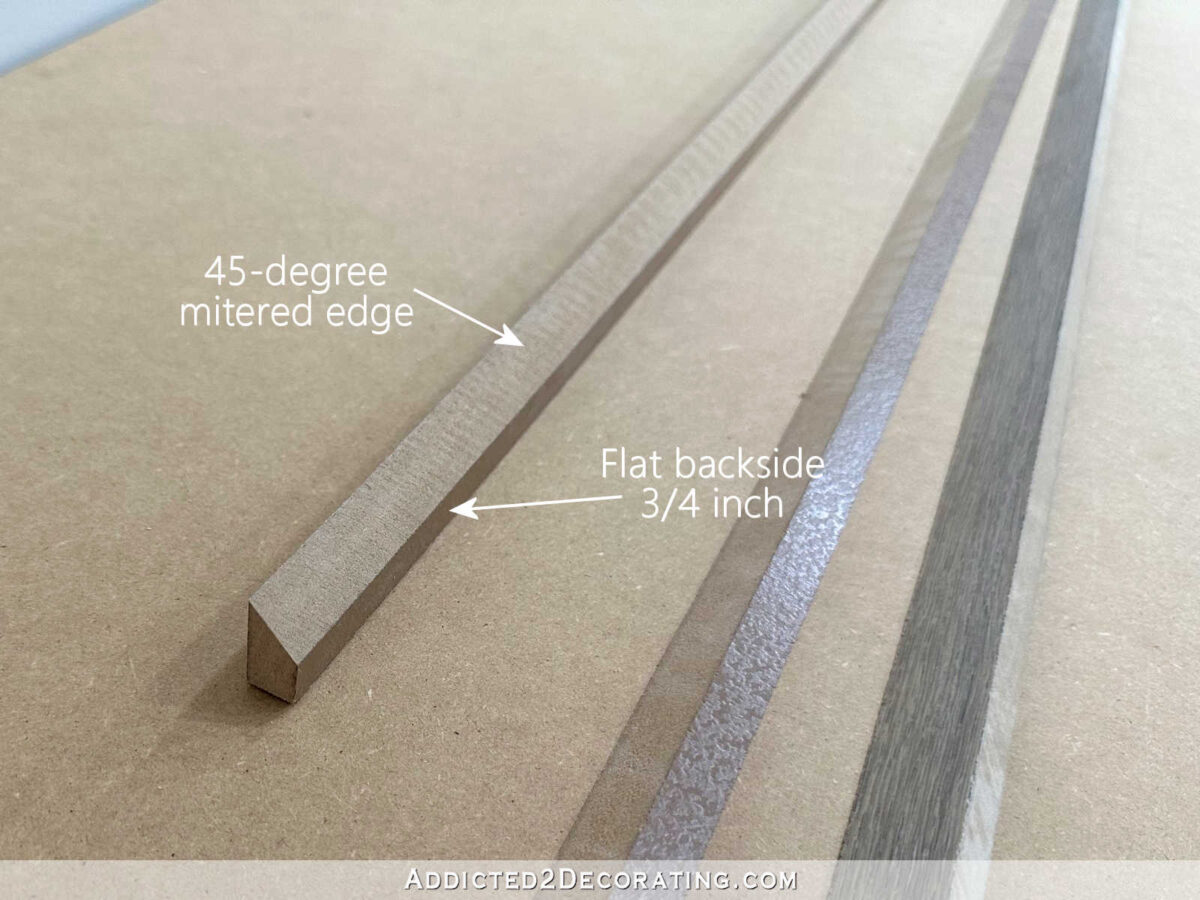

That prime mitered edge doesn’t present from the entrance, however right here’s a view of the again aspect of that piece. Hopefully you possibly can see how the highest edge is mitered at 45 levels.

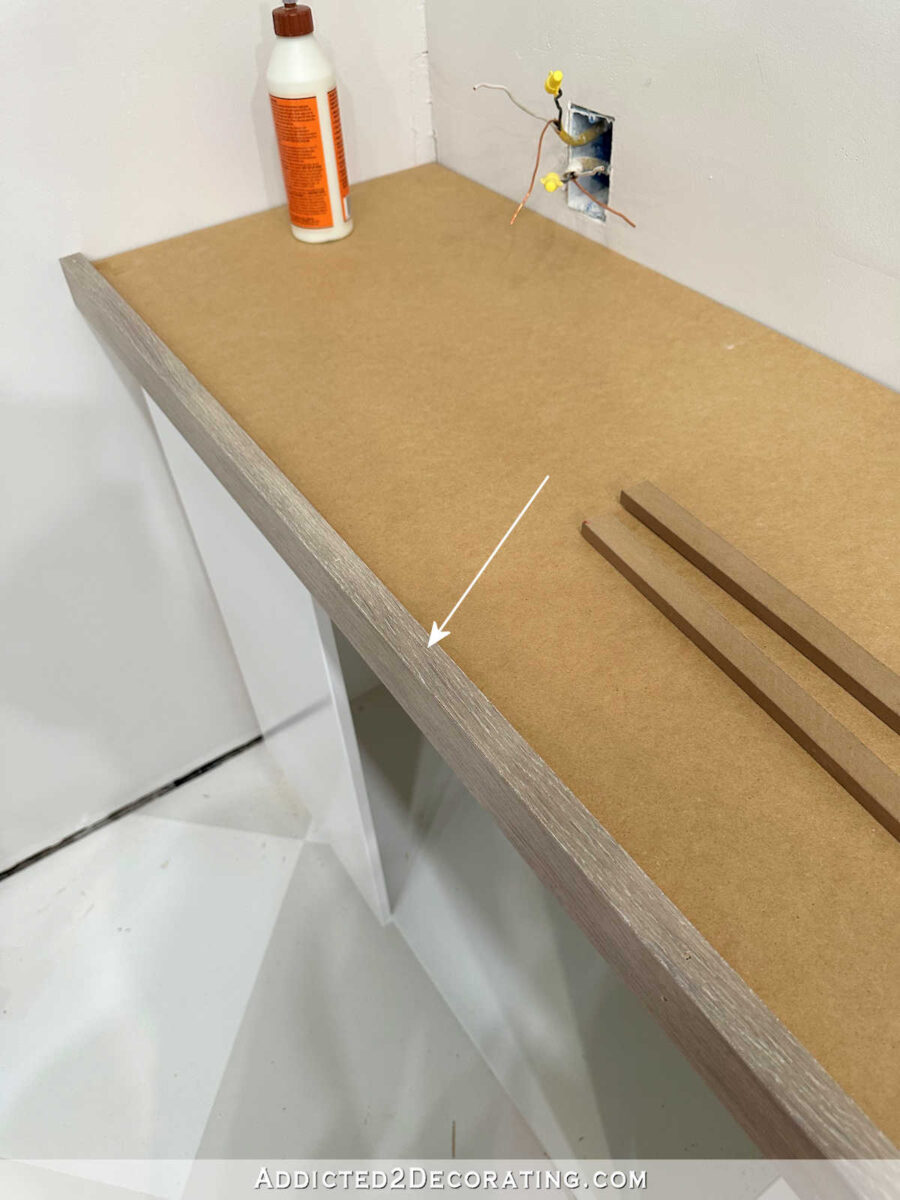

And for those who couldn’t see it within the image above, hopefully you possibly can see the highest mitered edges on the nook of this countertop or the place that entrance piece meets the wall.

As soon as the entrance items had been hooked up, I lower the items that will be hooked up to the highest to complete off that entrance piece. Once more utilizing my desk noticed, I lower them in order that the flat bottom of those items was 3/4 inch large, and these additionally had a 45-degree mitered edge.

After which I hooked up these in order that the 2 mitered edges met and gave the looks of a stable entrance piece of wooden. I glued and nailed these items on in the identical manner I did the entrance items.

As soon as these two items had been hooked up, that is what it seemed like…

Once more, remember that the images I confirmed above of the steps I took on the entrance edge had been all footage of the opposite countertop within the room, and on that countertop, I used a double thickness of three/4 MDF as the bottom for the countertop. That will have made the completed countertop two inches thick, which is simply too thick for my style, so I solely used one thickness of three/4 MDF as the bottom for the lengthy countertop, making the completed countertop 1 1/4 inches. That seemed a lot better.

So the remainder of the steps I’ll present you on the precise 20-foot countertop that I completed. Though, the remainder of the steps are extremely easy.

I began through the use of my desk noticed to chop off the tongue and groove edges of each piece of flooring. Why? As a result of most laminate flooring or prefinished flooring has apparent grooves between the boards once you put them collectively the right manner (i.e., utilizing the tongue and groove on the boards). Even when they don’t look apparent once you’re purchasing for flooring, they’ll be apparent once you attempt to use them for a countertop. So I simply ran every board via my desk noticed twice and lower off the tongue and groove on all sides.

After which I crammed within the countertop space, beginning on the entrance and dealing my technique to the again, with the trimmed items. It was like placing collectively a quite simple puzzle made for a 3-year-old. 😀 A few of the items needed to be lower to size utilizing my miter noticed, and the very again row needed to be ripped on the desk noticed to suit the remaining area. However apart from that, it was extremely simple.

As soon as I had the items match collectively and the countertop utterly coated, I eliminated the items row by row and numbered the backs in order that I’d know which row to position every bit, and which order to put in them. After which, utilizing a 6-inch curler, I utilized two coats of Contact Cement to the again of every piece, letting the primary coat dry totally earlier than making use of the second.

With these flooring boards positioned apart to dry, I utilized two coats of Contact Cement to the MDF, letting the primary coat dry totally earlier than making use of the second.

As soon as the Contact Cement was dry on the MDF, I started placing my massive puzzle again collectively, beginning on the entrance and dealing my technique to the wall. Placing every little thing again collectively took about fifteen minutes, if even that lengthy. It was so fast and simple.

As I put every bit in place, I pressed it down (particularly specializing in the corners) as exhausting as I might to ensure it was making good contact with the MDF and sticking correctly. After which as soon as the entire boards had been in place, I went again and pressed every little thing down yet another time. If I had a flooring curler, this may have been an excellent use for it.

At that time, it seemed fairly good, nevertheless it nonetheless wasn’t completed.

Since the entire items had been lower on the desk noticed and miter noticed, they didn’t match collectively completely. I imply, they had been an excellent match, however not an ideal match. A few of the boards had tiny cracks between them like this…

So I took a scrap piece of the flooring to Dwelling Depot and had them coloration match the darkest coloration within the flooring as carefully as potential, after which I introduced that residence and combined a few of that paint into latex caulk.

I had them match the darkest coloration within the flooring as a result of the white of the caulk would lighten the colour as soon as it was combined.

After which I used my most trusted and most used software ever (my finger) and crammed within the cracks with the coloured caulk. You may see one of many little cracks alongside the entrance fringe of the countertop within the picture under. This was earlier than caulking.

I simply smeared it on with my finger, ensuring that I pressed it down into the crack…

After which after I wiped off the surplus with a moist rag, it seemed a lot better! No extra darkish crack.

I’ll in all probability return and do a second coat as a result of I believe including the latex paint to the caulk made the caulk shrink greater than typical because it dried. However that can be a fast and simple course of.

I’m so happy with how this countertop turned out! And I can’t imagine I made a 20-foot-long countertop for round $300. I don’t assume you possibly can beat that! 😀

Once more, I’ll should take higher footage later within the day when the solar isn’t coming via these home windows so immediately, however I believe you possibly can see it properly sufficient even with the solar.

This truly exceeded my expectations, and was a lot simpler to make than the pantry countertop that I made utilizing actual hardwood flooring that had the be utterly sanded and completed as soon as the boards had been put in. With this, all that was wanted after the boards had been put in was a bit little bit of caulking. You may’t beat that!

And now…lastly…I get to place the higher cupboards in place on both finish of this countertop and canopy up the areas that haven’t any wallpaper. You could discover that the very again nook on every finish doesn’t have a bit of flooring hooked up.

That’s as a result of I used to be actually one flooring board in need of protecting each counter tops, and there was completely no manner I used to be going to buy one other full package deal of this flooring only for one further board, so I simply made certain the uncovered areas could be immediately under the higher cupboards. 😀 I’ll discover another 1/2-inch materials to fill in these areas earlier than setting the higher cupboards in place.

Now that the countertop is completed, the following steps can be placing collectively the higher cupboards and trimming these out, trimming out the underside cupboards, and ending {the electrical} shops within the backs of the cupboards. I’ve already received one outlet in place, however I’ve three to go. After which the scary half. I’ve to chop 3-inch holes within the countertop for the countertop grommet shops. Yikes! That’s scary to me, nevertheless it needs to be carried out if I would like quick access to electrical shops on this wall.

Addicted 2 Adorning is the place I share my DIY and adorning journey as I rework and adorn the 1948 fixer higher that my husband, Matt, and I purchased in 2013. Matt has M.S. and is unable to do bodily work, so I do nearly all of the work on the home on my own. You may study extra about me right here.

[ad_2]

Source link