[ad_1]

Yesterday, I completed the fundamental construct of the carcass for the DIY chest of drawers that I’m constructing to go between the vanities in our rest room. Since our vanities wanted to be wheelchair accessible, I constructed desk bases with turned legs for these. You may click on right here to see the main points of that challenge. However these don’t permit a lot room for storage, so this storage cupboard will go between these table-style vanities and supply all of the storage we’d like.

I acquired the carcass constructed and veneered with walnut veneer. Right here’s the way it appears to be like proper now…

Oh nicely. Clearly, it’s removed from completed. I nonetheless must construct drawer bins, drawer fronts, add a high, and add trim across the backside. However it’s getting there!

Oh nicely. Clearly, it’s removed from completed. I nonetheless must construct drawer bins, drawer fronts, add a high, and add trim across the backside. However it’s getting there!So let me present you the way I constructed and veneered the fundamental carcass.

I began through the use of my desk noticed to chop two items of three/4-inch plywood to 35 inches excessive by 18.5 inches large. These would type the perimeters of the cupboard. Then I lower 4 items (solely three present beneath) of 1″ x 4″ lumber to the completed width of the cupboard minus 1.5 inches.

Now let me clarify. I’d usually use strong plywood for the backing of a cupboard. However plywood is dear proper now, and I’ve had this lumber available for a really very long time now with no plans for it. So I made a decision to make use of what I’ve available. It received’t present on the completed cupboard because it’ll be up towards the wall, however you may actually substitute plywood for the again as an alternative of utilizing 1″ x 4″ lumber.

Utilizing my Kreg Pocket Gap Jig, I drilled 4 pocket holes into every finish of every of the 1″ x 4″ boards.

After which with one of many aspect items mendacity flat on the ground, I screwed the backer boards onto the aspect plywood piece as proven beneath.

Right here’s what that appeared like with all 4 assembled…

In the event you use a plywood again, you’ll do the exact same factor besides that your pocket holes might be extra evenly spaced alongside the sting of the plywood piece.

Then I stood that assembled part upright and hooked up the opposite aspect plywood piece.

With these all assembled, that is what it appeared like from the entrance…

And that is what it appeared like from the again…

Subsequent, I lower one other piece of plywood to part off the 2 banks of drawers. I lower this piece 35 inches excessive, however solely 17.75 inches large (the width of the aspect plywood items minus the three/4 inch for the again boards).

After marking and measuring the place the again boards would line up towards this plywood, I drilled three pocket holes in every part…

Then I marked the middle of every again board, lined up the plywood piece in order that it was centered on these marks, and screwed the plywood to the again boards utilizing the pocket holes I simply drilled.

As soon as once more, in the event you use plywood in your backing, you may simply house these pocket holes extra evenly throughout the peak of the again plywood piece.

Right here’s an in depth up take a look at these assembled items…

And right here’s what the entire carcass appeared like at this level…

Subsequent, I used my desk noticed to tear a chunk of 1-inch lumber down to suit onto the sting of the plywood. Utilizing my miter noticed, I lower it to size, after which hooked up it utilizing wooden glue and 1.5-inch 18-gauge nails in my nail gun.

Right here’s how that appeared…

Earlier than attaching walnut to the sides of the outer plywood items, I wanted to veneer the insides of these items.

Two issues to notice:

(1) Sure, it might have been simpler to veneer these items earlier than assembling the carcass, and if you are able to do that, I counsel doing it that means. The explanation I didn’t is as a result of plywood and veneer want a minimum of 24-48 hours to acclimate in the identical room earlier than placing them collectively. My plywood hadn’t acclimated that lengthy, however I didn’t need that to cease me from making progress. So I began the construct, after which utilized the veneer as quickly as I might within the course of. However in the event you can apply this piece of veneer earlier than attaching it to the again, that’s preferable.

(2) I put the plywood on the within with the grain going horizontally to be able to not waste veneer. This received’t present on the completed cupboard, so I’m not likely apprehensive concerning the grain going the unsuitable means. However I did wish to veneer it as a result of it’s finest apply to veneer either side to attenuate the probabilities of the plywood warping.

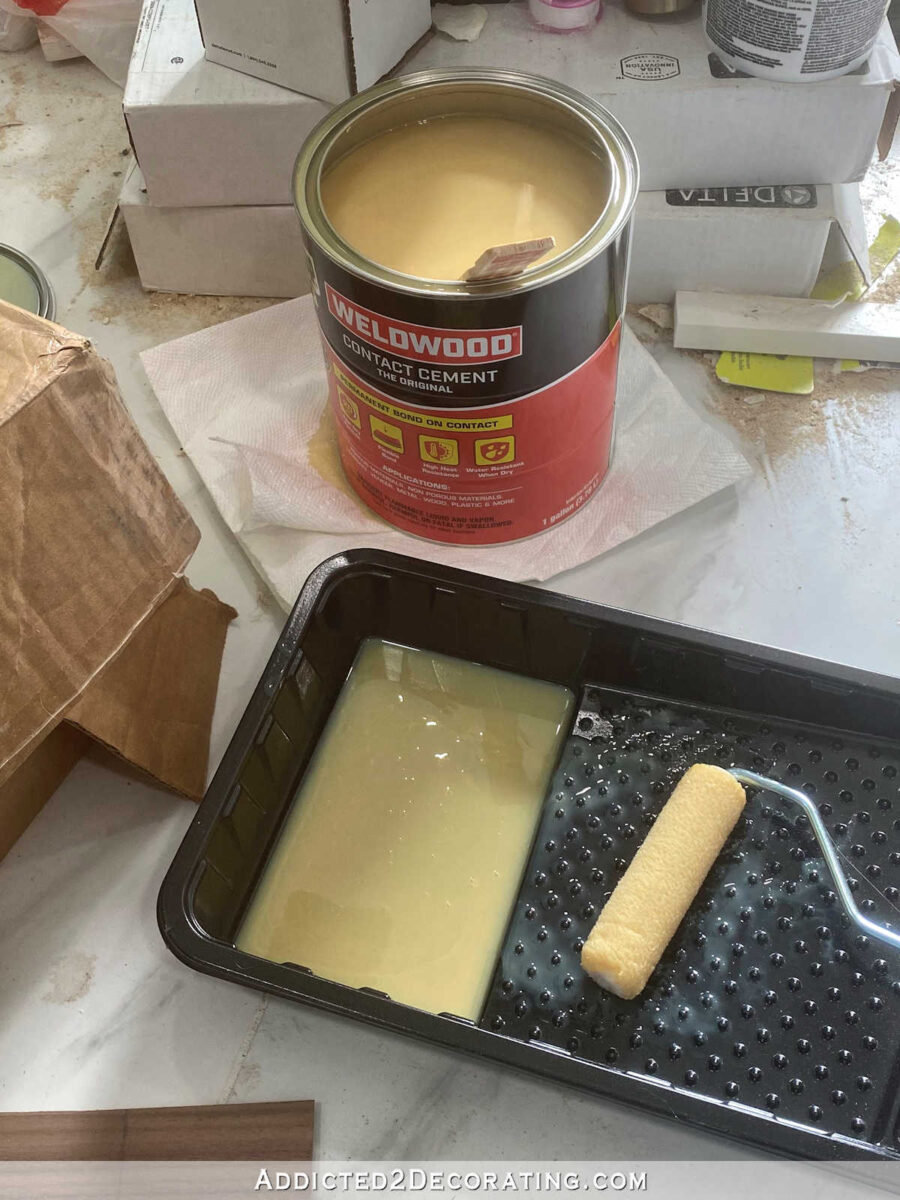

So, with all of that mentioned, I lower a chunk of veneer for the within of every aspect plywood piece. I lower them in order that they have been only a bit bigger than the plywood. To connect the veneer, I used Weldwood Contact Cement, making use of it with a 4-inch curler to the plywood and to the again of the veneer.

I used two coats on every, letting the primary coat dry totally earlier than making use of the second coat. When it’s dry sufficient, it will get shiny, but it surely isn’t sticky once you contact it.

Then with the cupboard mendacity on its aspect, I fastidiously utilized that veneer to the within of the aspect piece, and burnished it with a scrap block of walnut (not the lengthy piece you see within the picture beneath) to get all the air bubbles and ridges of contact cement out.

That is the piece of walnut that I used to get all the air bubbles and glue ridges out from the veneer.

I sanded it to take away all the actually sharp edges first in order that it wouldn’t go away any scrapes or gouges within the veneer, and it labored splendidly.

Subsequent, I flipped the cupboard onto the opposite finish and rolled the contact cement onto the veneer and the plywood. Whereas these have been drying, I used my X-Acto knife with a brand new blade to trim off the surplus veneer from the primary aspect that I had veneered.

With each of the within aspect panels veneered and trimmed, that is what it appeared like…

Then I positioned the cupboard on its again, and hooked up the items of walnut to the sides of the aspect plywood items in the identical means I did the middle piece.

Right here’s what the carcass appeared like with these items hooked up to all three plywood items…

At this level, I used to be prepared to connect the rails to create the person sections for the drawers. I lower these out of 1″ x 2″ walnut lumber, and with the cupboard standing upright and dealing from high to backside, I hooked up the rails within the left part utilizing 1.5-inch 16-gauge nails shot via the plywood on both sides and into the ends of the 1″ x 2″.

I hooked up them in order that the skinny edge was dealing with ahead, and the broader aspect was dealing with up in order that the width of the rails would match the thickness of the walnut-edged plywood items.

All the rails within the left part might be hooked up in the identical means with a nail gun, however for the correct part, I might solely connect the outer aspect with the nail gun (since I couldn’t nail via the middle plywood piece with a rail in my means). The within needed to be hooked up utilizing pocket screws, so I needed to drill pocket holes into one finish of these rails.

Right here’s what it appeared like with the primary two rails hooked up alongside the highest…

These first two rails have been simple to line up alongside the highest fringe of the plywood, however for the remainder of the rails, I had to make use of my pace sq. to verify they have been sitting sq. contained in the stiles earlier than attaching them.

And right here’s what it appeared like with all the rails hooked up. I made the highest two drawer sections about 4.5 inches excessive, and the underside two drawer sections about 9 inches excessive.

You could discover that I hooked up the underside rails in order that the large aspect was dealing with ahead…

I did this as a result of this large board shall be used alongside the underside to complete it off, and I wished to make certain there was no house between these two boards.

I’ll be utilizing my router to create a routed design within the high of that board earlier than reducing and attaching it to the underside of the cupboard.

With all the rails hooked up, I might lastly veneer the skin of the aspect panels.

I stood the cupboard on finish as soon as once more, and rolled on the contact cement all the best way to the sting. I wished the veneer to cowl over all the nail holes in addition to the sting of the walnut piece.

I hooked up that veneer the very same means as the opposite items — burnishing it down with the walnut block and trimming the surplus with the X-Acto knife. As soon as the sides have been sanded, it appeared fairly excellent! I do want I had gotten an image earlier than including the wooden filler, although.

And after repeating that veneering course of on the opposite aspect, the fundamental carcass was completed.

As you may see, I acquired the aspect apron piece on the vainness hooked up. So now there’s no ugly pine exhibiting on the vainness.

I hope to get all the drawer bins and drawer fronts completed for this cupboard this weekend, so we’ll see the way it goes. I can inform you one factor, although. I’m so excited and motivated to get this DONE! I’m completely thrilled with how all the things is popping out, and I can’t wait to get all the things constructed in order that I can put the Rubio Monocoat end on all of this walnut. I feel it’s going to be stunning!

Addicted 2 Adorning is the place I share my DIY and adorning journey as I transform and embellish the 1948 fixer higher that my husband, Matt, and I purchased in 2013. Matt has M.S. and is unable to do bodily work, so I do the vast majority of the work on the home on my own. You may study extra about me right here.

I hope you’ll be a part of me on my DIY and adorning journey! If you wish to observe my initiatives and progress, you may subscribe beneath and have every new publish delivered to your electronic mail inbox. That means you’ll by no means miss a factor!

[ad_2]

Source link