[ad_1]

Yesterday, I confirmed y’all of the completed DIY table-style rest room self-importance that I constructed for our grasp rest room rework. So in the present day, I wished to again up a bit and present the step-by-step course of for the way I made the drawer fronts.

That is Half 2 of this self-importance challenge. You’ll be able to click on right here to search out Half 1 exhibiting the essential construct for the desk base and drawer packing containers. So right here’s one other have a look at the completed self-importance with the drawer fronts completed and hooked up.

Hopefully you’ll be able to see that the drawer fronts are made up of a body with a recessed panel set inside. The body is minimize out of stable walnut lumber, and the recessed panel is 1/2-inch plywood lined with walnut wooden veneer.

With that primary data in thoughts, let me present you ways I made these drawer fronts.

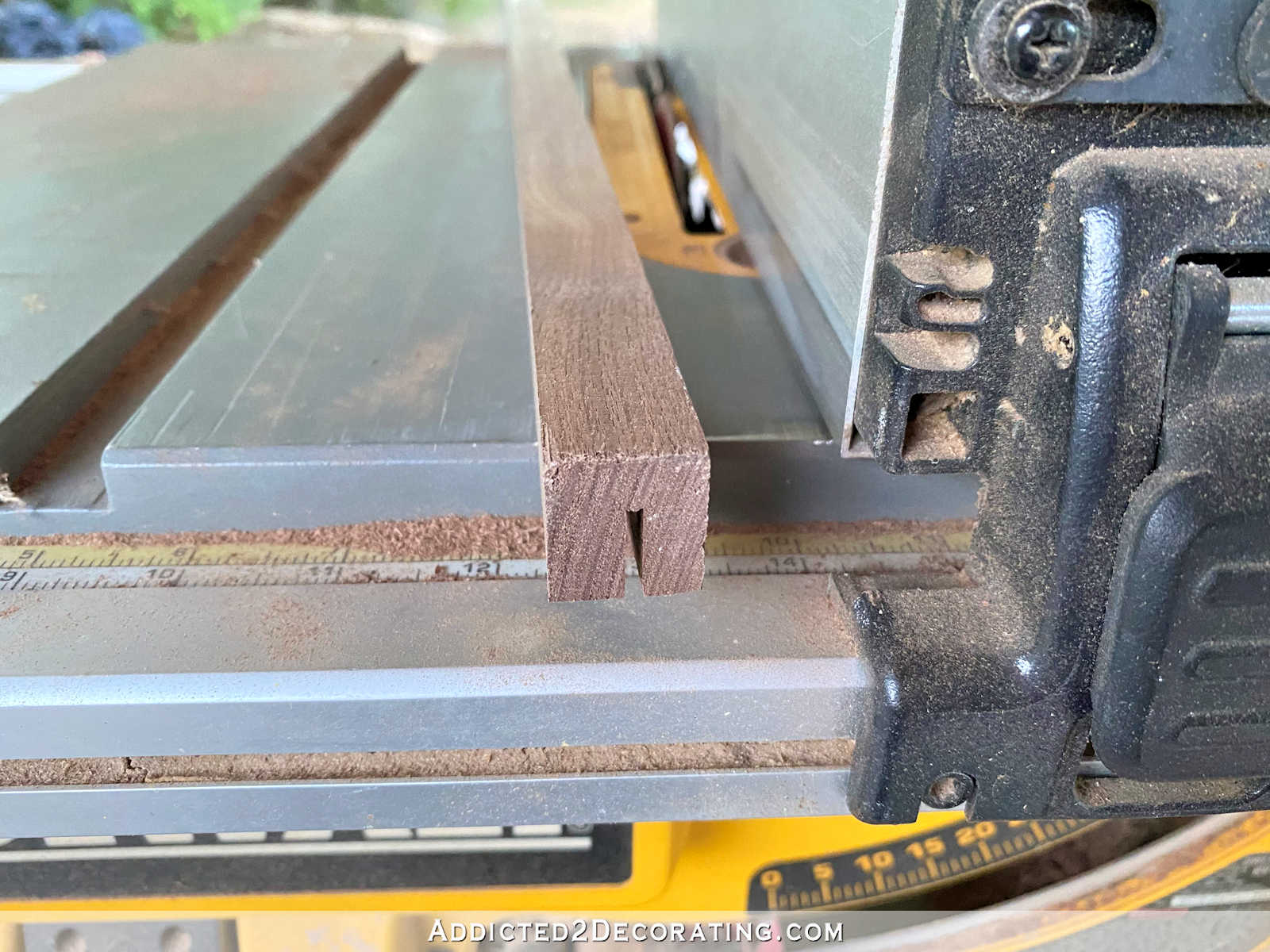

I began with 1″ x 3″ walnut lumber and minimize them down into items which are principally giant sq. dowels. (1″ lumber is definitely 3/4-inch thick, so I set my desk noticed fence to tear 3/4-inch widths and minimize the items in order that they had been 3/4-inch by 3/4-inch.) Then I measured the thickness of the fabric I might be utilizing for the recessed panels (two thicknesses of walnut veneer and one piece of 1/2-inch plywood). That measurement was roughly 5/8-inch, so I set my blade to that depth, and set the fence somewhat over 1/4-inch from the blade, and ran the entire items by way of the noticed to create the primary minimize to make the rabbet to carry the recessed panel.

After which I flipped the piece over and re-set the noticed blade and fence in order that the following move would take away that piece fully. This was the step that took me a few tries to get proper, and I ended up ruining a few items of walnut. However right here’s what the profile seemed like after each cuts had been made. The skinny aspect that’s left (dealing with left) would be the high of the body, and the thick aspect that’s left (dealing with up) would be the aspect of the body.

It’s crucial to chop the entire items on the similar time. In different phrases, I’m making two vanities and a storage cupboard, so I minimize the entire body items on my desk noticed on the similar time. That method they’d all be completely constant. I’ve discovered that if I’ve to return and re-cut items like that, and attempt to get my noticed set precisely the identical method I had it the primary time, it’s virtually not possible to get it excellent. And when that occurs, assembling frames with elements that got here from totally different items minimize at totally different occasions could cause issues that can end in a lower than fascinating end result.

With all of these items minimize, I then used my miter noticed to chop the person items for the frames, mitering every finish at a 45-degree angle.

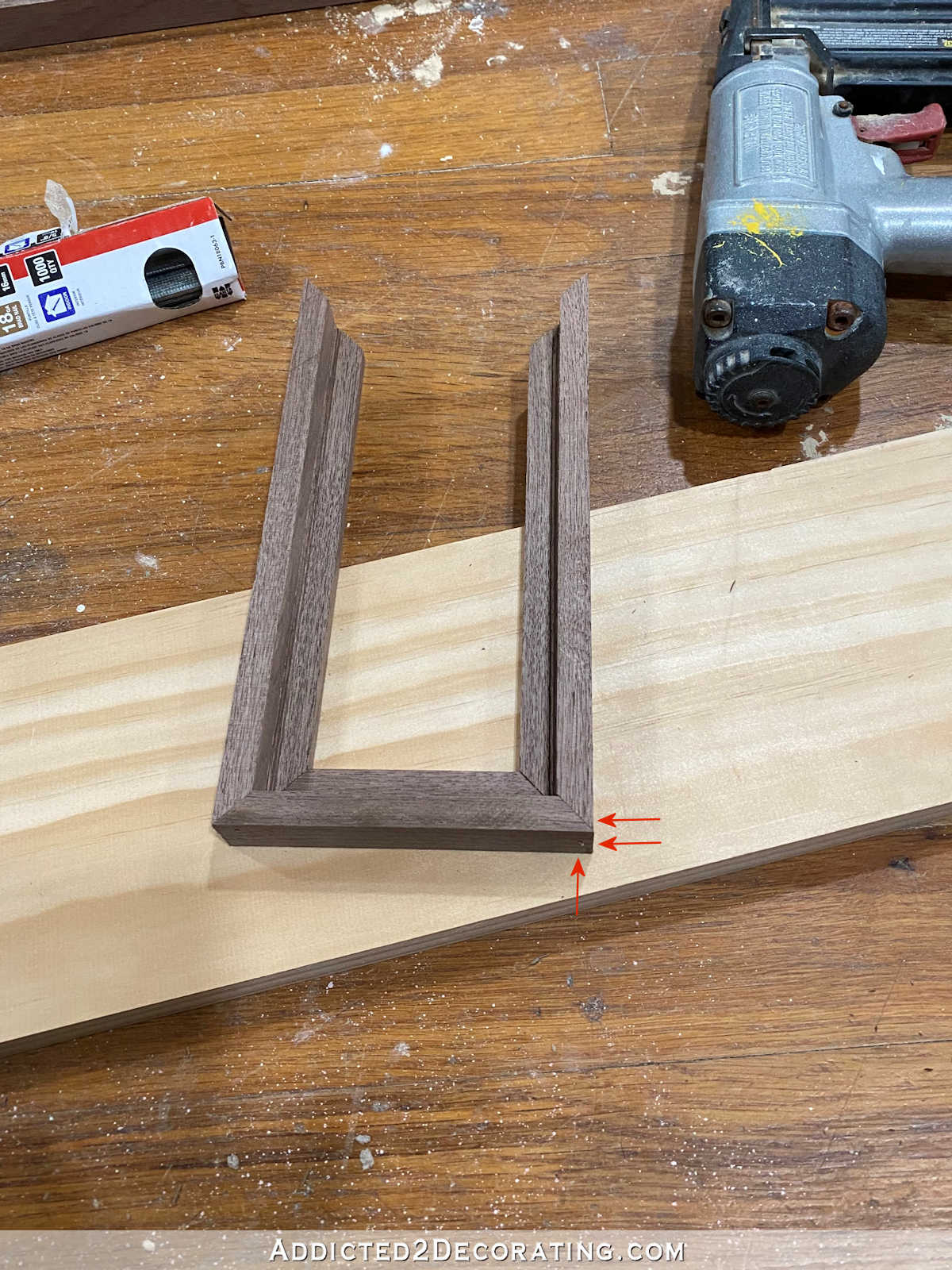

To assemble the frames, I used wooden glue and 5/8-inch 18-gauge nails. In the event you don’t wish to use nails, then you’ll be able to simply use glue and 45-degree clamps. I’m extra of an instantaneous gratification sort of individual, so ready for wooden glue to dry isn’t actually my model. 😀 I opted for the instant gratification of nailing the items collectively.

As I labored my method round every body, I used three nails (these nails are actually tiny) in every nook — two from the precise aspect (one on high, one on backside), and one centered from the underside. See the arrows on the image beneath if that description doesn’t make sense.

Right here’s what the again of the body seemed like when it was assembled.

And right here’s a have a look at the entrance.

I used to be really fairly happy with my mitered corners, however I at all times fill and sand my mitered corners on each challenge I do, so this was no exception. I used Goodfilla water-based wooden filler in walnut to fill the mitered joints and the nail holes on the edges.

After it dried, I sanded the body by hand with 120-grit sandpaper. I typically sand my challenge as much as 220-grit, however the directions for the clear end I’m going to make use of on this self-importance say to sand solely as much as 120-grit. You’ll be able to see beneath the sanded body in comparison with the unsanded body.

Right here’s a have a look at how the perimeters turned out after sanding.

Subsequent, I used my desk noticed and miter noticed to chop items of 1/2-inch plywood for the inserts.

To stick the walnut wooden veneer, I used Weldwood Contact Cement and a 4-inch curler.

I utilized two coats of contact cement to the plywood and to the again of the veneer, letting it dry fully between coats (which solely took a couple of minutes).

After which I rigorously aligned the veneer and smoothed it onto the plywood. You solely have one shot at this. In the event you get it on crooked, there’s actually no going again. It’s fairly straightforward to work with these little items, however bigger items require rather more care and endurance.

Then I received a scrap piece of walnut and sanded the perimeters in order that they weren’t fairly so sharp…

And I used that piece of walnut to burnish the walnut veneer and ensure it was completely flat and easy, and there have been no air bubbles or ridges of contact cement trapped beneath.

I repeated this course of on the again of the plywood as properly. The one distinction is that for the entrance, I pre-cut the veneer. For the reason that edges of the entrance could be hidden by the body, it didn’t must be as exactly minimize. For the again, I minimize the piece of veneer bigger than the plywood, after which after it was adhered, I rigorously minimize off the surplus utilizing an X-Acto knife to provide these edges a cleaner and extra exact look.

Then I positioned the veneered plywood into the body, and secured the items along with extra 5/8-inch 18-gauge end nails within the corners (which don’t present beneath as a result of I forgot to take an image of it after nailing it into place).

However you’ll be able to see it on this image beneath. I might have wooden stuffed and sanded these little nail holes, however to be trustworthy, they don’t hassle me.

However I did wish to guarantee that the backs of the drawer fronts had the walnut veneer on them as a result of the backs present within the mirror when the drawers are open.

Plus, it’s observe to veneer either side of plywood. In the event you simply do one aspect, your veneered plywood is extra liable to warping. That’s not likely a difficulty with tiny items like this, but it surely’s undoubtedly a difficulty with bigger items. So it’s only a good observe to at all times veneer either side.

To connect the drawer fronts to the drawer packing containers, I used each wooden glue (slower drying however longer lasting) and scorching glue (for instant maintain). Simply an FYI, once I use scorching glue for my initiatives, I’m not speaking about these little craft glue weapons that you simply get a craft retailer. I’m speaking in regards to the large one you can buy within the device division of Dwelling Depot.

On the middle pretend drawer entrance, I used a tiny little bit of scorching glue on the again of the drawer entrance to get it into place, after which I went again with 4 scrap items of wooden, and used my scorching glue gun to connect these items to the again of the drawer entrance and the aspect body of the self-importance base.

After which the drawers had been prepared for his or her jewellery…

This was a really enjoyable challenge, and I’m so happy with the way it turned out! Now I want another self-importance and a storage cupboard, and that can wrap up the large initiatives on this rest room.

Addicted 2 Adorning is the place I share my DIY and adorning journey as I rework and adorn the 1948 fixer higher that my husband, Matt, and I purchased in 2013. Matt has M.S. and is unable to do bodily work, so I do the vast majority of the work on the home on my own. You’ll be able to be taught extra about me right here.

I hope you’ll be a part of me on my DIY and adorning journey! If you wish to comply with my initiatives and progress, you’ll be able to subscribe beneath and have every new publish delivered to your e mail inbox. That method you’ll by no means miss a factor!

[ad_2]

Source link