[ad_1]

Textual content description supplied by the architects.

The JST Manufacturing Engineering Middle is the Japanese electrical connector firm’s facility in Swatara Township, Pa. The 52,000 square-foot design, improvement, and manufacturing middle homes workplaces, connecting decks, a lunchroom, and manufacturing house with a machine middle, automation space, high quality management, and delivery and receiving.

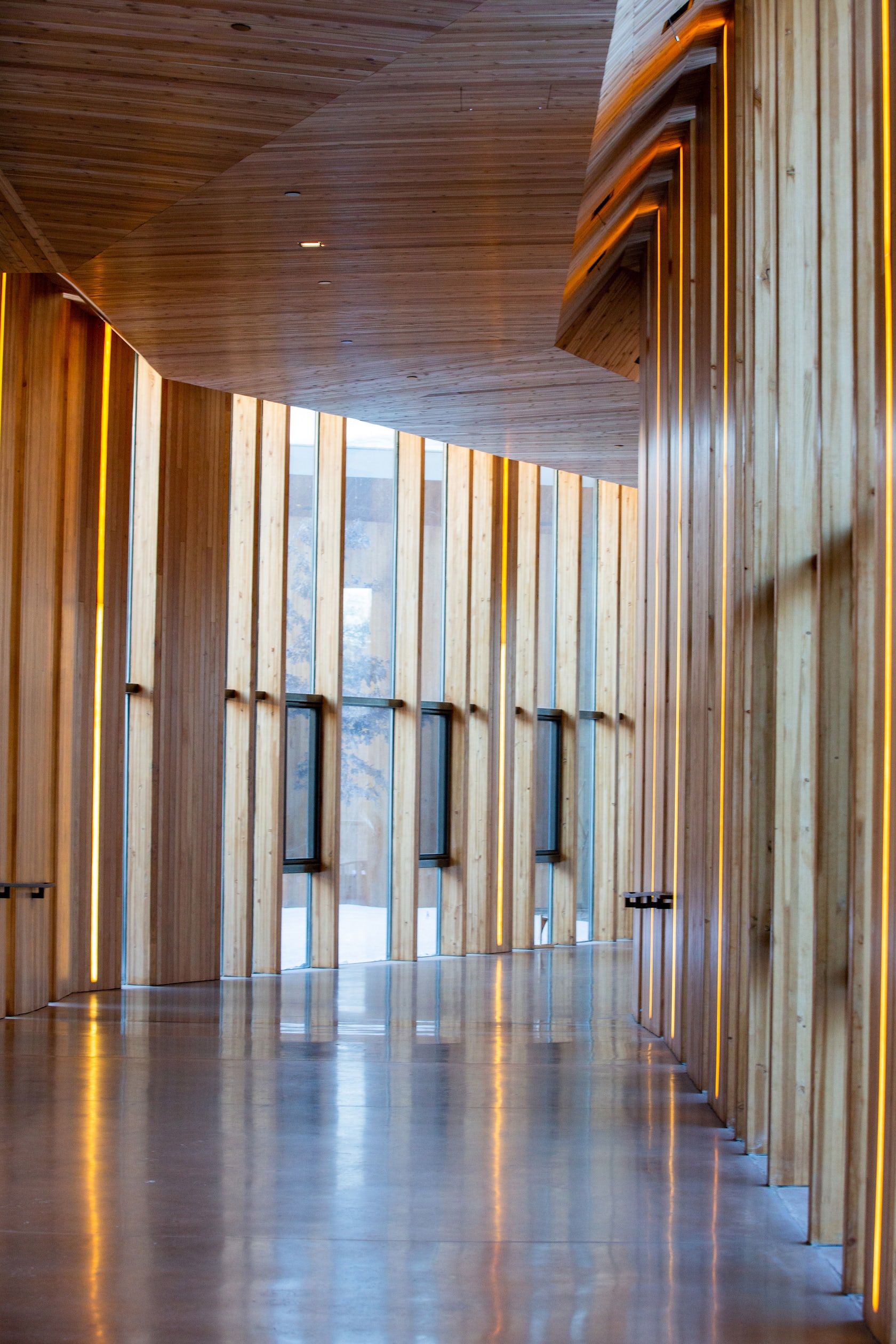

At first look, the JST Manufacturing and Engineering Middle’s stunning and expansive single-level timber and glass design captivates you.

© YKK AP America, Inc.

The geometry of the constructing in and of itself is hanging, with greater than 70 corners in and out. It attracts you in because it “flows down a mild collection of sculpted swales for greater than half a mile,” in accordance with B+D Builders. The constructing represents a deep connection to nature, taking inspiration from tree roots.

© YKK AP America, Inc.

Because the constructing flows again, it turns into taller and wider to characterize this progress. This collection of related wooden buildings reveal an surprising, novel and but sustainable design method utilizing poplar laminated beams, deep roof overhangs, flow-through air flow and a floor-to-ceiling glass exterior (composed of 40% glass). The wooden parts of the constructing are spectacular, having been minimize, milled and assembled individually, so not one of the 5,000+ items used are alike.

© YKK AP America, Inc.

A mission of this magnitude, with intricate timber and glass design element and aggressive sustainability necessities, meant that every one events collaborated typically to establish challenges and overcome them. Many challenges have been referenced by B+D Builders, together with the positioning gradation, soffit pitch, and lengthy beam spans. Nevertheless, probably the most notable feat of glass and glazing engineering was YKK AP’s creation of what we imagine to be the primary thermally damaged veneer wall system.

© YKK AP America, Inc.

This progressive resolution was born out of the necessity to create a seamless sightline and lengthen the movement of the timber to the body of the constructing, matching the prevailing depth of the three-inch timber beams and attaining the floor-to-ceiling glass and flow-through air flow. A horizontal aluminum tube was then set above and beneath the casement window, in order that the YES SSG TU Vented Window could possibly be set into the curtain wall pocket for simple set up.

© YKK AP America, Inc.

The champagne painted end of the sustainable aluminum framing system blends impeccably nicely with the encircling timber. That is really an intriguing and authentic architectural mission that leveraged each accomplice’s capabilities to the best extent to convey an inspiring imaginative and prescient to actuality..

© YKK AP America, Inc.

JST Manufacturing Engineering Middle Gallery

[ad_2]

Source link