[ad_1]

Allwork.Area spoke with Michael Fried, the CEO of Bene, to find out about their strategy to sustainable, round design via biodegradable supplies and 3D printing – which has been greater than two centuries within the making.

This text was initially revealed by Allwork.Area.

It’s not usually you come throughout an organization within the workspace sector that’s been working for over 20 years, not to mention 200. However Bene has.

Established by a carpenter in 1790, a yr after the French Revolution started, Bene is the world’s longest-running workplace furnishings model.

However don’t let its longevity idiot you into considering it’s caught up to now.

Within the phrases of Michael Fried, Bene’s CEO, “we’re an organization with quite a lot of custom however we’re not a conventional firm. Our imaginative and prescient for many years has been to grow to be, be and keep the worldwide reference for progressive working, and that is what we nonetheless try for.”

Bene’s headquarters are located in what massive metropolis dwellers may describe because the ‘center of nowhere’, in Waidhofen, Austria – midway between Salzberg and Vienna.

The agency’s development began to essentially speed up within the twentieth century.

“When workplaces began to grow to be extra industrialised, we have been the primary ones developing with some strong devoted workplace furnishings,” says Fried.

At first of the twenty first century Bene launched its Parcs furnishings assortment to cater for the rising coworking sector. The gathering continues to be going robust as we speak.

Now, Bene is popping its consideration to sustainability.

“In case you see the place we’re dwelling and dealing in the midst of the forest, and the uncooked materials that we’re working with, you realize that sustainability needs to be a part of our story. Our timber in Austria is a sustainable product as a result of our reforesting is a benchmark.”

Practically 50% of Austria is forested and the nation is a frontrunner in reforestation, as demonstrated via initiatives akin to The Austrian Forest Dialogue.

“However whenever you produce belongings you at all times have some type of carbon footprint,” admits Fried.

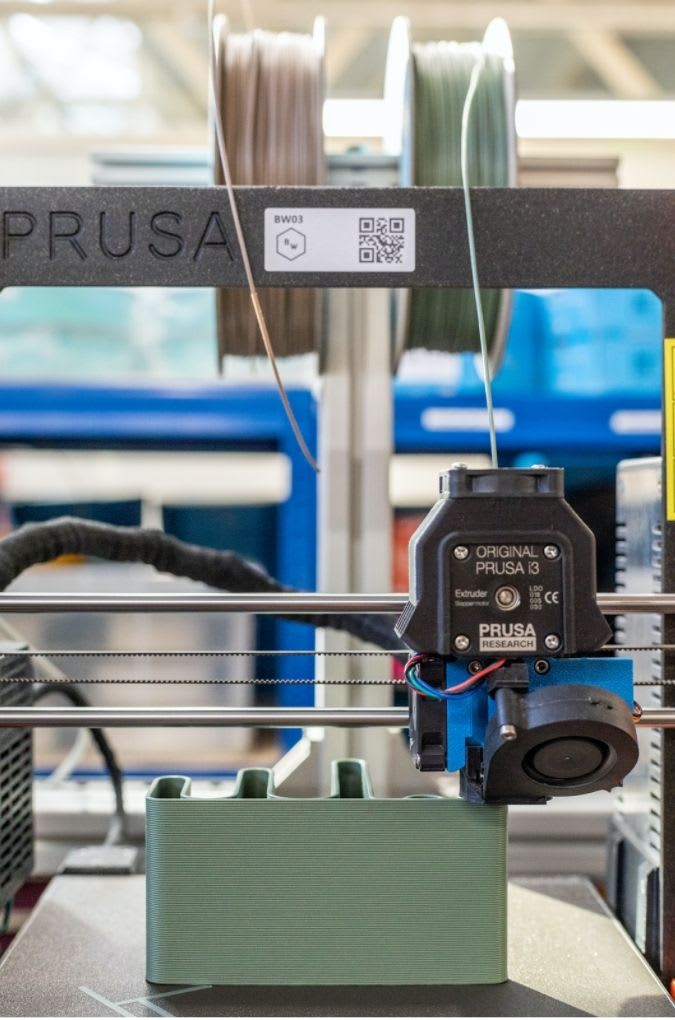

“We’re minimising this and taking the following step in direction of sustainable manufacturing by 3D printing merchandise utilizing already-used biodegradable supplies.”

In November 2021 Bene launched bFRIENDS – its first, 3D-printed, round manufacturing equipment assortment created from 100% recycled post-consumer bioplastic.

The gathering was designed in collaboration with Pearson Lloyd, Bene’s long-standing design companions, and manufactured by the London-based eco startup, Batch.Works.

The recycled plastic is sourced by Reflow, a social enterprise specialising in recycling the bioplastics utilized in merchandise akin to meals packaging, for the needs of 3D printing.

“It’s a group of desktop equipment comprising pen holders, trays, cellular machine holders [etc.] created from discarded meals packaging,” says Fried.

21 merchandise can be found in ten colors, nonetheless as a result of the 3D printing course of is so quick and versatile, prospects can request customized colors when ordering in bulk.

3D printing works by build up the merchandise layer by layer in a single steady line, versus chopping away from a bigger materials block or via injection moulding, each of which are inclined to generate extra waste materials.

Batch.Works’ 3D printing services are wind powered, so manufacturing is energy-efficient, requiring simply 1.35 KW for each kilogram of printed product.

Round economic system is the important thing idea behind the brand new assortment.

In response to Zero Waste Scotland, “a round economic system is achieved by designing merchandise well with their complete life cycle in thoughts, re-using and repairing to increase their helpful life, after which when their life is deemed over, remanufacturing to create new merchandise from previous.”

Within the spirit of a round economic system, prospects are inspired to recycle their bFRIENDS merchandise after they now not have a necessity for them. Any undesirable equipment may be returned to Bene to be recycled into new merchandise.

Apparently, bFRIENDS isn’t Bene’s first foray into 3D printing, per se.

In 2016 it equipped the furnishings for the world’s first 3D printed workplace. Located in Dubai, the concrete constructing was printed with a 6×46 metre 3D printer.

The important thing query is: is Bene planning to scale up the undertaking and begin printing 3D furnishings?

It’s a chance Fried’s actually all for.

“In fact! This might be the longer term. The bFRIENDS assortment shouldn’t be a trial; it’s clearly the place we’re going. Within the subject of manufacturing, we’ll nonetheless should see. As we’re a premium supplier, we’re not making compromises on the standard.”

Fried needs to keep away from ‘greenwashing’, which is when manufacturers exaggerate their environmental credentials to mislead eco-conscious shoppers. Take bamboo as an illustration, a fabric that Bene makes use of in a few of its product strains.

Though bamboo is a sustainable crop within the sense that it’s fast-growing, requires no fertiliser and self-regenerates from its personal roots, Fried says that we are able to’t gloss over the carbon emissions concerned in transporting the uncooked materials from international locations like China.

“We wish to make a step in direction of actual sustainable efforts and so this [3D printing] is what we’re specializing in.”

Within the short-term, Bene goes to be specializing in increasing its equipment product line. The crew is maintaining a tally of which colors are proving common, and can proceed to develop the bodily language of the gathering.

Fried additionally hopes that, within the close to future, 3D printing services will grow to be extra widespread, enabling designers to leverage a distributed community of native manufacturing hubs.

The provision of 3D printing will considerably cut back delivery prices and minimise carbon emissions related to the transportation of supplies and items.

“Slicing delivery distances for each uncooked supplies and completed merchandise, and shortening provide chains and lead instances, is one thing that all of us should try for.

“The 3D printers may be standing wherever. We’re going to have some in our major markets right here in Austria, Germany and France. This would be the way forward for our business within the long-term.”

[ad_2]

Source link